Copper Pipes and Tubings

ASTM B280 ACR Tubes WILKO ® KOREA

WILKO ASTM B280 copper tubes play a crucial role in plumbing and HVAC systems, offering durability, reliability, and efficiency.

Specifications

- ASTM B280

Summary

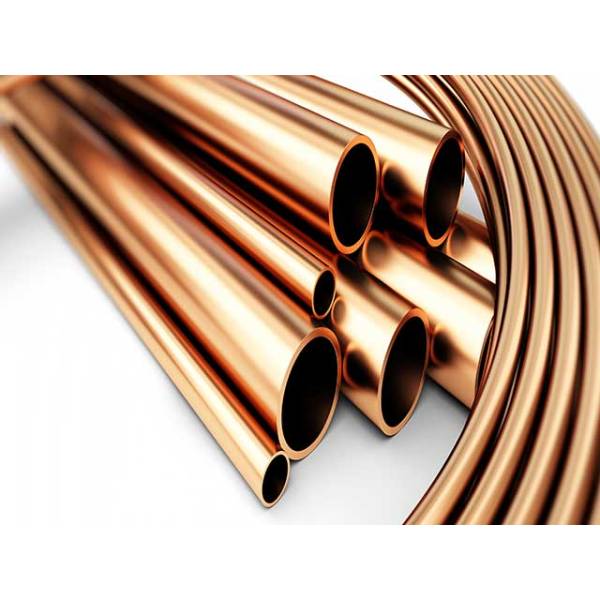

- WILKO ASTM B280 Tubes are Standard Specification for Seamless Copper Airconditioning & Refrigeration Tubes (ACR). Tubes come mainly designated as Type L.

- These pipes are manufactured using pure copper deoxidized with phosphorus, leaving relatively high residual phosphorus content. They are mostly available in hard drawn temper but ALL tubes are pre-cleaned with Nitrogen and capped to maintain internal cleanliness under normal conditions of handling and storage.

- Product under this specification can be furnished in either O60 (soft annealed) or H58 (drawn general purpose) temper. Coils are normally in O60 temper and straight lengths in H58 temper.

- Very popular in Commercial, Residential and Industrial ACR applications.

- WILKO ASTM B280 ACR Tubes are made of top quality material and tested to ensure optimum performance.

Introduction:

Types of Copper Tubes Covered:

- Type K: Featuring the thickest walls, Type K tubes are suitable for high-pressure applications such as underground water service lines and mains.

- Type L: Type L tubes have medium thickness walls and are commonly used for above-ground applications including potable water distribution and HVAC systems.

- Type M: With relatively thinner walls, Type M tubes are primarily used in residential and light commercial plumbing where pressures are lower.

Key Specifications:

- Dimensions: ASTM B280 specifies the nominal sizes, outside diameters, wall thicknesses, and lengths of copper tubes. These dimensions vary depending on the type and application of the tube.

- Tolerances: The standard outlines acceptable variations in dimensions to ensure uniformity and quality in manufacturing.

- Chemical Composition: ASTM B280 mandates the chemical composition of the copper used in manufacturing tubes, ensuring they meet specific purity and quality standards. Copper, being the primary material, should meet certain requirements for composition and impurity levels.

- Testing and Quality Control: The specification includes requirements for testing methods to verify compliance with dimensional, chemical, and mechanical properties. These tests are crucial for maintaining quality and consistency in production.

Benefits of ASTM B280 Copper Tubes:

- Corrosion Resistance: Copper exhibits excellent resistance to corrosion, ensuring longevity and reliability in plumbing and HVAC systems.

- Thermal Conductivity: Copper is a highly efficient conductor of heat, making ASTM B280 tubes ideal for HVAC applications where heat transfer is critical.

- Versatility: With different types available, ASTM B280 copper tubes cater to a wide range of applications, from high-pressure water lines to refrigerant distribution systems.

- Ease of Installation: Copper tubes are relatively easy to work with, allowing for straightforward installation, bending, and joining techniques, thereby reducing installation time and labor costs.

Conclusion: