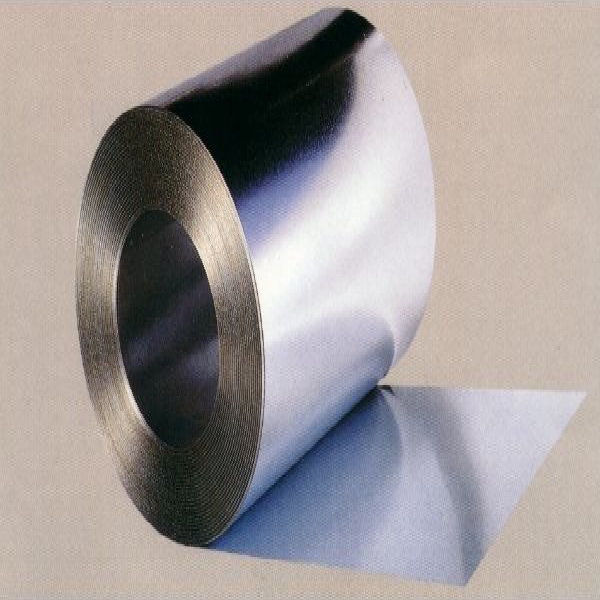

Stainless Steel

SUS 316

Specifications

- SUS 316

- SUS 316L

Summary

- Food preparation equipment especially in chloride environments

- Laboratory benches and equipment

- Coastal architectural panelling, railings and trim

- Boat fittings

- Chemical containers, including for transport

- Heat exchangers

- Woven or welded screens for mining, quarrying and water filtration

- Threaded fasteners

- Springs

Introduction:

Stainless steel 316 is a highly versatile and widely used austenitic stainless steel alloy known for its excellent corrosion resistance, high temperature strength, and mechanical properties. Composed primarily of iron (Fe) with chromium (Cr), nickel (Ni), and molybdenum (Mo) as the primary alloying elements, stainless steel 316 offers a unique set of characteristics that make it suitable for a wide range of applications across various industries. Here's a detailed write-up on stainless steel 316:

Composition:

Stainless steel 316 belongs to the austenitic family of stainless steels and typically consists of the following composition:

- Chromium (Cr): 16-18%

- Nickel (Ni): 10-14%

- Molybdenum (Mo): 2-3%

- Iron (Fe): Balance

- Carbon (C): ≤0.08%

- Manganese (Mn): ≤2%

- Silicon (Si): ≤1%

- Phosphorus (P): ≤0.045%

- Sulfur (S): ≤0.03%

The precise composition may vary slightly depending on specific manufacturing requirements and standards.

Properties:

- Excellent Corrosion Resistance: Stainless steel 316 offers superior corrosion resistance in a wide range of corrosive environments, including seawater, acidic and alkaline solutions, and chemical processing environments. The addition of molybdenum enhances its resistance to pitting and crevice corrosion, making it suitable for marine and aggressive chemical applications.

- High Temperature Strength: Stainless steel 316 exhibits good high-temperature strength and oxidation resistance, retaining its mechanical properties at elevated temperatures. It is suitable for applications involving exposure to high temperatures, such as heat exchangers, exhaust systems, and furnace components.

- Mechanical Properties: Stainless steel 316 has excellent mechanical properties, including high tensile strength, yield strength, and hardness. It provides reliable performance in structural and load-bearing applications requiring strength and durability.

- Weldability: Stainless steel 316 is readily weldable using standard welding techniques, such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). It forms strong and durable welds with minimal risk of sensitization and subsequent corrosion in the heat-affected zones.

- Hygiene and Cleanability: Stainless steel 316 is non-porous and resistant to bacterial growth, making it ideal for applications requiring hygiene and cleanability, such as food processing equipment, pharmaceutical manufacturing, and medical devices.

- Aesthetic Appeal: Stainless steel 316 has a smooth and polished surface finish, which enhances its aesthetic appeal. It is commonly used in architectural, decorative, and interior design applications where appearance is important.

- Low Maintenance: Stainless steel 316 requires minimal maintenance and upkeep due to its inherent corrosion resistance and durability. It is easy to clean and maintain, making it suitable for long-term use in various applications.

Applications:

- Marine and Coastal Structures: Stainless steel 316 is extensively used in marine and coastal structures, such as boats, ships, offshore platforms, and seawater desalination plants. Its superior corrosion resistance makes it ideal for applications exposed to seawater and salt spray.

- Chemical Processing: Stainless steel 316 finds applications in the chemical processing industry for manufacturing reactors, vessels, tanks, piping systems, and fittings. It is used in corrosive environments where resistance to acids, alkalis, and chlorides is critical.

- Food and Beverage Industry: Stainless steel 316 is widely used in the food and beverage industry for manufacturing processing equipment, storage tanks, piping systems, and utensils. Its corrosion resistance, hygiene, and cleanability make it ideal for food handling and processing applications.

- Medical Devices and Pharmaceuticals: Stainless steel 316 is employed in the medical and pharmaceutical industries for manufacturing surgical instruments, medical implants, and equipment requiring biocompatibility, sterilizability, and corrosion resistance.

- Automotive and Aerospace: Stainless steel 316 finds applications in the automotive and aerospace industries for manufacturing exhaust systems, fasteners, structural components, and engine parts. Its high strength and corrosion resistance make it suitable for demanding automotive and aerospace applications.

- Heat Exchangers and HVAC Systems: Stainless steel 316 is used in heat exchangers, HVAC systems, and refrigeration equipment for its high temperature strength and corrosion resistance. It ensures reliable performance and longevity in heat transfer applications.

Conclusion:

Stainless steel 316 is a highly versatile and widely used alloy with excellent corrosion resistance, high temperature strength, and mechanical properties. Its unique combination of properties makes it suitable for a wide range of applications across various industries, including marine, chemical processing, food and beverage, medical, automotive, aerospace, and HVAC. Whether in corrosive environments, high temperature applications, or hygiene-sensitive applications, stainless steel 316 continues to demonstrate its value as a reliable and effective engineering material.

Share