Brass

Free Machining Brass

Specifications

- C3604, C2801, CZ108 BS2870 Cu63Zn37, C2720, C2700

Summary

- Free Machining Brass is an alloy of copper and zinc. While it is harder than copper, it is more easily machined and cast.

- Bright yellow finish and very corrosion resistant.

- Easily hard and soft soldered

- Good heat/ electrical conductor.

- Hardware: Gears and pinions

- Industrial: Automatic high speed screw machine parts

Introduction:

C3604, also known as C36000, is a widely used brass alloy characterized by its excellent machinability. This alloy falls under the category of free machining brass, owing to its specific composition designed to optimize machining operations. Here's some detailed information about C3604 free machining brass:

Composition:

C3604 brass is primarily composed of copper (Cu) and zinc (Zn), with additional elements to enhance machinability. Its typical composition includes approximately:

- Copper (Cu): 60-63%

- Lead (Pb): 2.5-3.7%

- Zinc (Zn): 35.5-36.6%

Trace elements: Iron (Fe), Tin (Sn), and other elements in minor amounts.

Properties:

- Machinability: The defining characteristic of C3604 brass is its exceptional machinability. The inclusion of lead in the alloy promotes the formation of short, manageable chips during machining, reducing tool wear and improving machining efficiency. This property makes it ideal for high-speed machining operations, resulting in enhanced productivity.

- Corrosion Resistance: C3604 brass offers good corrosion resistance, particularly in atmospheric and aqueous environments. It forms a protective oxide layer on its surface, which helps prevent corrosion and maintains the integrity of the material over time.

- Strength and Ductility: This alloy exhibits moderate strength and excellent ductility, allowing it to be easily formed, bent, and stamped into various shapes without compromising its mechanical properties. It offers a good balance between strength and malleability, making it suitable for a wide range of applications.

- Electrical Conductivity: Like other brass alloys, C3604 possesses good electrical conductivity, making it suitable for electrical and electronic applications. It is commonly used in connectors, terminals, and electrical components where reliable conductivity is essential.

- Thermal Conductivity: C3604 brass exhibits decent thermal conductivity, enabling efficient heat dissipation. This property is beneficial in applications where thermal management is critical, such as heat exchangers and radiator components.

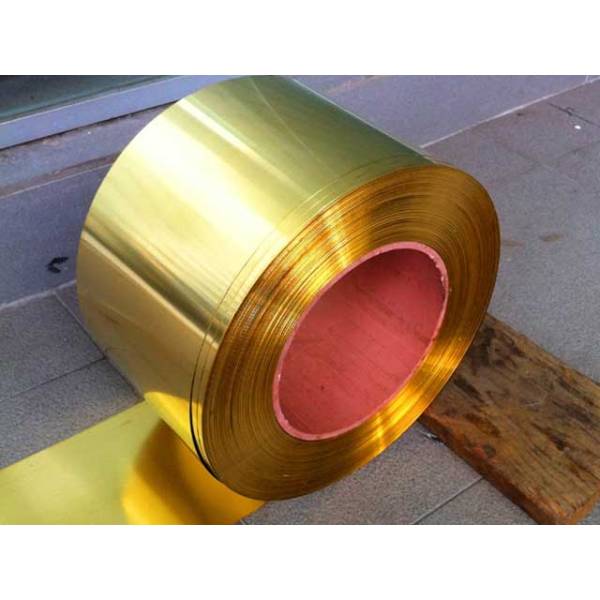

- Appearance: With its characteristic golden-yellow color, C3604 brass offers an attractive appearance. It can be polished to a high luster, making it suitable for decorative applications in architecture, interior design, and ornamental fixtures.

Applications:

- Precision Components: C3604 brass is widely used for manufacturing precision components such as fittings, valves, gears, and fasteners due to its excellent machinability and dimensional stability.

- Automotive Parts: It finds extensive use in automotive applications, including valve guides, bushings, connectors, and various engine components, where its machinability and mechanical properties are highly valued.

- Electronics: C3604 brass is employed in electrical and electronic components such as connectors, sockets, switches, and terminal blocks due to its good electrical conductivity and corrosion resistance.

- Plumbing Fixtures: Brass alloys, including C3604, are commonly used in plumbing fixtures and fittings due to their corrosion resistance, machinability, and ability to withstand high water pressure and temperature fluctuations.

- Decorative and Architectural Elements: Its attractive appearance and ease of fabrication make C3604 brass suitable for architectural hardware, decorative accents, and ornamental fixtures in both residential and commercial settings.

Conclusion:

C3604 free machining brass is a versatile alloy known for its excellent machinability, corrosion resistance, strength, and electrical conductivity. Its unique combination of properties makes it indispensable across various industries, including automotive, electronics, plumbing, and architecture. Whether for precision engineering or decorative applications, C3604 brass continues to be a preferred material due to its reliability, performance, and ease of fabrication.

Share